Address

1st Floor, Building 7, No. 1, Lianxing Erheng Road, Yinbian, Jiahe Street, Guangzhou, Guangdong, China

Work Hours

Professional 7*24H Online Support

Address

1st Floor, Building 7, No. 1, Lianxing Erheng Road, Yinbian, Jiahe Street, Guangzhou, Guangdong, China

Work Hours

Professional 7*24H Online Support

$2,500.00

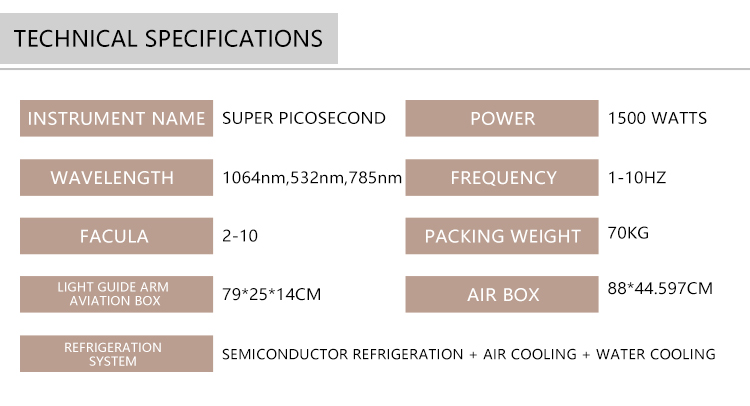

Model:PL1010

Brand Name:YANMEI

Delivery Method: By Air, By DHL/TNT/FEDEX/UPS Express ,By Sea(Door To Door, Double tax)

OEM/ODM: Support,having been in the industry more than 10 years, all of our product lines can be fully customized to meet your specific needs at competitive prices.

Occasion: Beauty Salon,Hospitals,Clinic,Skin Care Centers,Spa,Home,etc ..

Machine Language: English (Support Customized System Language)

Warranty: lifelong after-sales service

Product Training: Get free one-on-one clinical operating training service.

Ee Certification: All have been approved by international certifications.

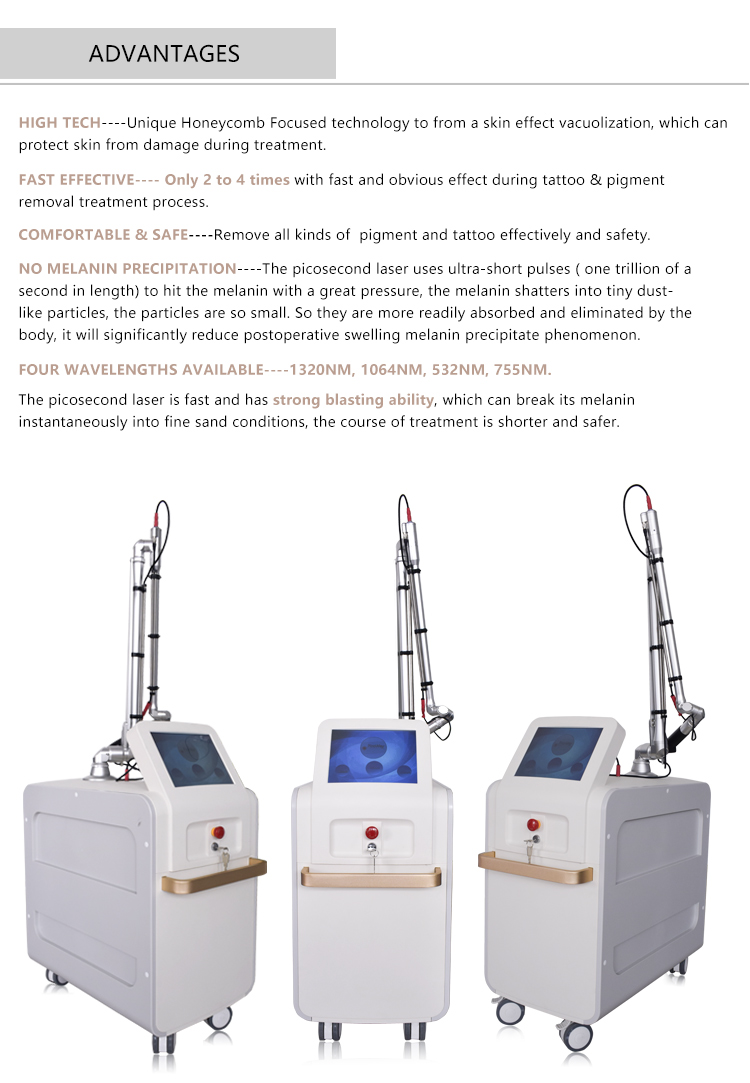

Picosecond lasers represent a sophisticated advancement in laser technology, characterized by their ability to generate extremely short pulses of light, lasting merely one trillionth of a second. The term “picosecond,” derived from the metric prefix ‘pico’ meaning one-trillionth, underscores the remarkable speed at which these lasers operate, allowing for unparalleled precision in various applications. In essence, picosecond lasers function by emitting high-energy light bursts that can be finely tuned in both duration and intensity, resulting in minimal thermal damage to surrounding tissues or materials.

The fundamental operation of picosecond lasers revolves around the electronic transition of photons within a gain medium, which is typically solid-state, gas, or fiber. When excited, this medium releases energy in the form of light pulses that are then compressed to achieve the picosecond range. This ultrafast pulse duration not only enhances the laser’s efficiency but also amplifies its capability to deal with intricate procedures in fields like medicine, manufacturing, and research. The brief duration of each pulse allows for selective absorption of light, which is particularly beneficial in medical applications where precise targeting of tissue is crucial.

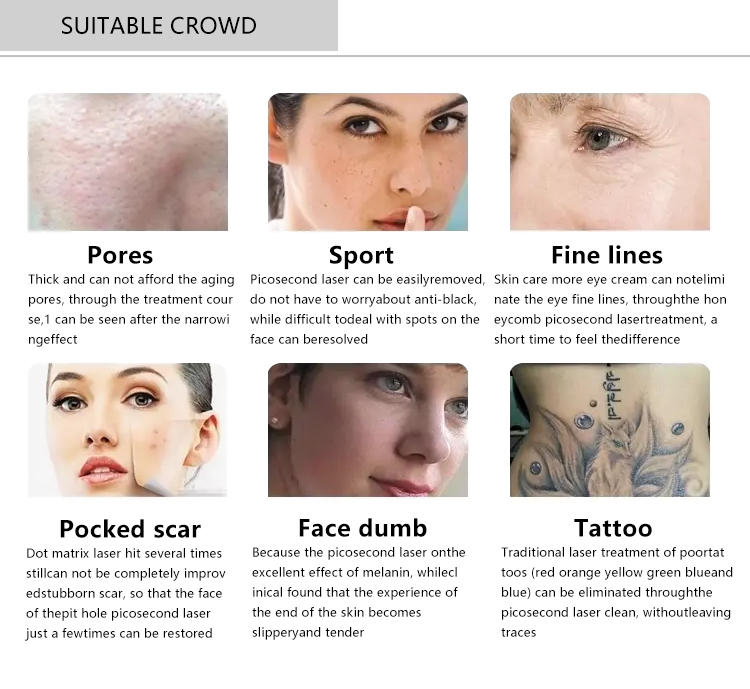

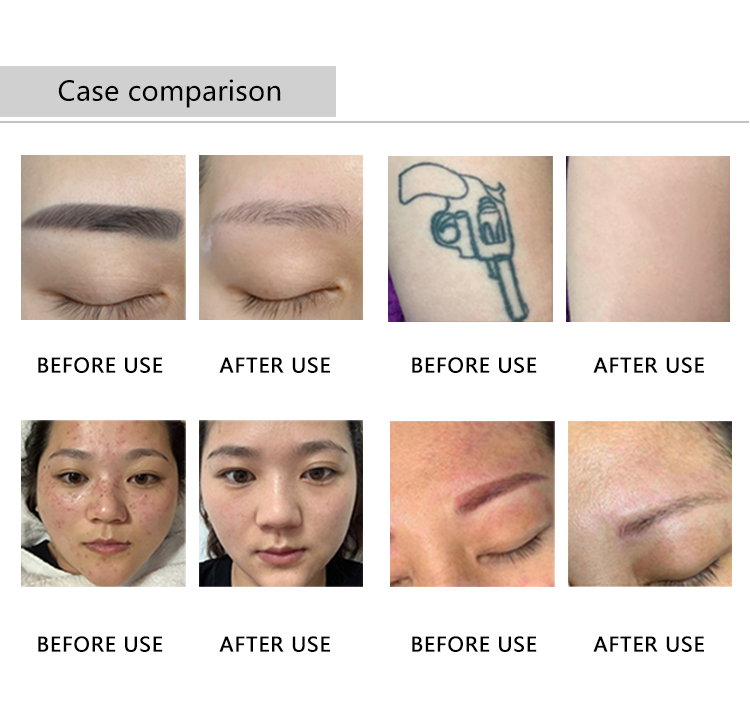

Comparatively, picosecond laser technology outperforms traditional laser systems by minimizing collateral damage while maximizing effectiveness. In the medical sector, for instance, picosecond lasers are employed for tattoo removal, skin rejuvenation, and cutting-edge surgical procedures, providing patients with quicker recovery times and reduced discomfort. Similarly, in manufacturing, they facilitate high-resolution micromachining and precision engraving, enhancing product quality and consistency. As research continues to expand the possibilities of picosecond laser applications, it becomes increasingly evident that this technology is poised to revolutionize numerous industries through its unmatched efficiency and precision.

Picosecond laser machines have emerged as a revolutionary tool in both medical and industrial fields, offering several distinct advantages over traditional laser systems. One of the primary benefits is enhanced precision. The technology behind picosecond lasers allows for extremely short pulse durations—measured in trillionths of a second. This rapid emission of energy enables highly controlled ablation, making them particularly suitable for delicate procedures in dermatology, such as skin rejuvenation and tattoo removal. By precisely targeting the desired area without affecting surrounding tissues, picosecond lasers significantly minimize collateral damage.

Another notable advantage is the reduction of thermal damage. The short pulse duration characteristic of picosecond lasers limits the amount of heat transferred to surrounding skin, thereby reducing the likelihood of post-procedural complications. In dermatological applications, this results in faster healing times and less discomfort for patients, as there is a lower risk of burns or scarring compared to longer-pulse lasers. Patients undergoing treatments, such as laser tattoo removal, can experience improved outcomes, with fewer sessions required to achieve satisfactory results, thereby enhancing overall patient satisfaction.

Moreover, picosecond lasers exhibit remarkable versatility in various applications. In addition to their role in dermatology, these advanced devices are increasingly utilized in industrial sectors. Applications such as micro-machining, where precision cutting and engraving are critical, benefit from the high energy and small spot sizes of picosecond lasers. They allow for intricate patterns and designs to be achieved on a wide array of materials, including metals, plastics, and ceramics, further expanding their industrial utility. Overall, the key advantages of picosecond lasers—enhanced precision, reduced thermal impact, and versatility—position them as invaluable tools in both healthcare and manufacturing environments.

Laser technology encompasses a wide array of systems, each tailored for specific applications. Among these, picosecond lasers have garnered attention for their unique characteristics, particularly in comparison to nanosecond and femtosecond lasers. The key difference lies in the pulse duration; picosecond lasers emit pulses lasting trillions of a second, while nanosecond lasers operate in the range of billionths of a second, and femtosecond lasers make use of pulsation durations in the order of quadrillionths of a second. This variation in pulse duration significantly impacts energy delivery and the effectiveness of the laser in various applications.

In terms of energy delivery, picosecond lasers are designed to deliver energy in a controlled manner, allowing for minimal thermal damage to the surrounding tissue. This precision is particularly vital in medical applications such as tattoo removal and skin rejuvenation. Conversely, the longer pulse duration of nanosecond lasers can result in greater thermal effects, potentially causing damage to adjacent tissues, which may limit their use in sensitive applications. Meanwhile, femtosecond lasers, with their ultrashort pulses, allow for extremely precise cutting and ablation but are often more costly and complex to operate.

From an effectiveness standpoint, picosecond lasers have shown superior results in the breakdown of pigments, making them particularly effective for tattoo removal and addressing pigmentation disorders. Their rapid pulse duration facilitates the effective fragmentation of ink particles, allowing the body to naturally eliminate these particles with less collateral damage. In contrast, while nanosecond lasers can also be effective for similar applications, their longer pulses sometimes require multiple treatment sessions and may present a higher risk of undesirable side effects.

However, picosecond lasers come with their own set of potential drawbacks. One such limitation is the cost; their advanced technology often results in higher initial investment, which may deter some clinics from adopting them. Overall, understanding the comparative benefits and challenges of picosecond lasers against other laser technologies enables informed decisions regarding their application in various fields.

The landscape of picosecond laser technology is poised for significant evolution as researchers and industry professionals explore emerging trends and advancements. One particularly promising area of development is the aim to enhance laser efficiency and performance. Innovations such as advanced cooling systems and improved cavity designs are expected to yield lasers that emit a higher output while consuming less energy. These enhancements not only promise economic advantages but also align with global sustainability goals, thereby making picosecond lasers an integral tool in eco-friendlier manufacturing processes.

Another vital trend involves the integration of picosecond lasers with cutting-edge technologies such as artificial intelligence (AI) and machine learning. By leveraging advanced algorithms, operators can optimize laser parameters according to specific material properties or desired outcomes. This integration has the potential to enhance process automation, thus creating high-precision and customized applications in fields ranging from materials processing to medical treatments. The synergy between laser technology and these digital innovations provides opportunities for more adaptive and responsive manufacturing environments.

Additionally, as research advances in materials science, we can anticipate the development of new substrates and compounds that can be processed with picosecond lasers. Innovations such as metamaterials and nanostructured materials may capitalize on the ultrafast laser’s precision and control, enabling novel applications in electronics, photonics, and biomedicine. The continuous exploration of material interactions within ultra-short pulse regimes will further expand the usability and versatility of picosecond lasers.

Overall, the future of picosecond laser technology shows immense promise. As industries increasingly recognize its potential, we can expect to see vast applications emerging in sectors such as automotive, aerospace, and even agriculture, thereby enhancing productivity and innovation on multiple fronts. As this technology continues to mature, its impact on various fields could be transformative, setting a new standard for precision and efficiency in laser applications.